AI: Key role of ASML in AI tech wave. RTZ #588

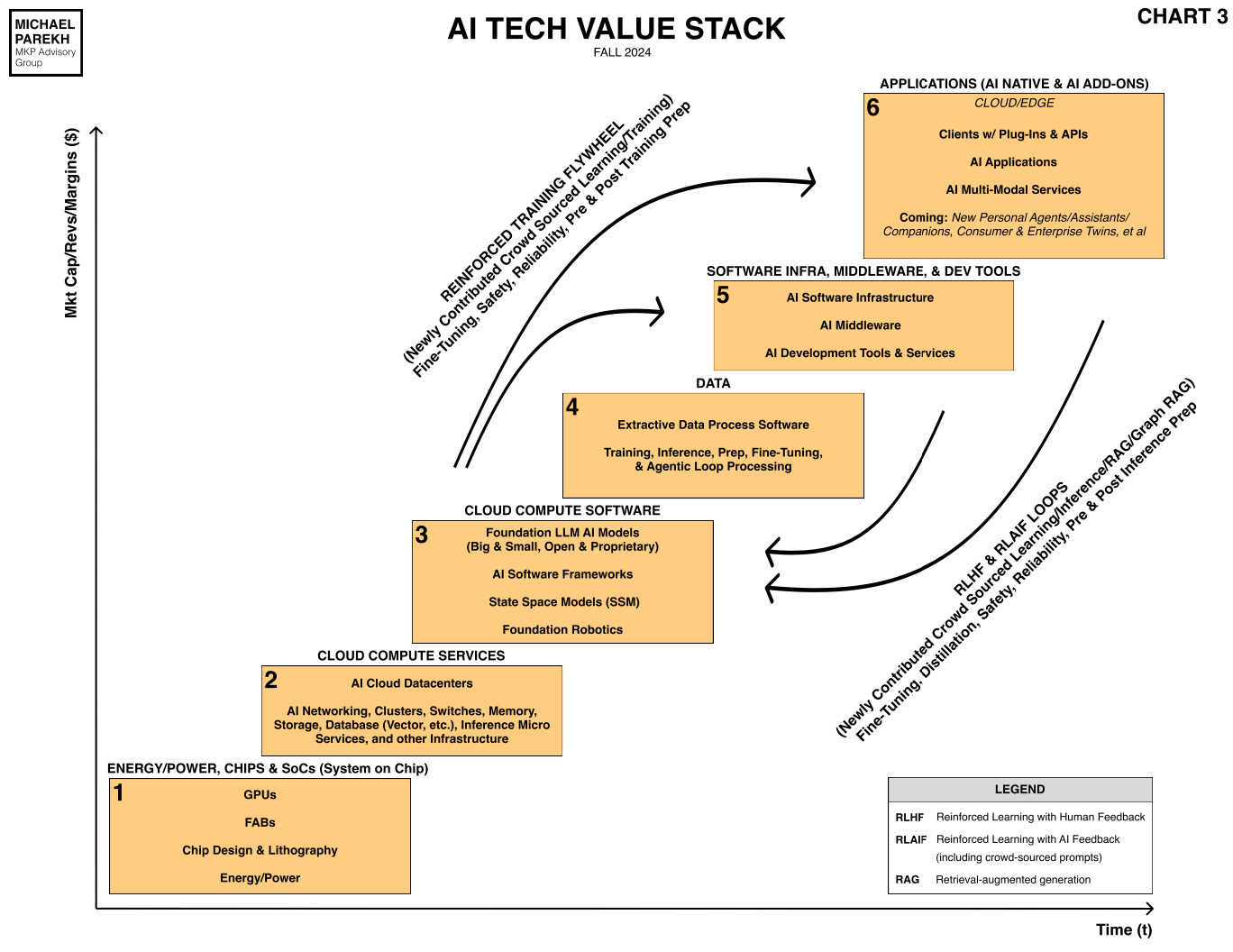

As I’ve outlined in my year-end pieces, 2025 will remain a continuing year for AI driven semiconductor chip stocks. I’ve long discussed companies like Nvidia (AI GPUs), TSMC (semiconductor fabs), SK Hynix (HBM memory), Broadcom (Custom AI Chips), ARM Holdings (mobile chip templates) are of course familiar core names in this AI Tech Wave. They all fall in Box 1 of the AI Tech Stack chart below.

Alongside the increasingly critical Power providers to ever larger AI Data Centers.

One less familiar, but equally critical name in the ‘Lithography’ category in Box 1 above, is the $280+ billion market cap, Dutch behemoth ASML Holdings , (Advanced Semiconductor Materials Lithography). As we go into a New Year, it’s timely to also focus on this critical player in the growth of AI and Tech.

The WSJ has a timely piece “It’s the Most Indispensable Machine in the World—and It Depends on This Woman”, introducing the company through the eyes of a highly trained engineer who runs one of its most advanced machines. It’s a helpful framing for the critical role of these machines by ASML:

“Brienna Hall has the most valuable role that you’ll never see at the most vital company that you’ve never heard of.”

“Until she began working at ASML last year, she didn’t know the first thing about the company. She also didn’t know what she would be doing as a customer-support engineer—a “fancy mechanic,” as she calls herself.”

“And she had absolutely no idea that it would be essential to the global economy.”

“When she reports for her shift at a chip plant, Hall slips into a bunny suit. She enters a room where the pristine air is 100 times cleaner than a hospital operating room’s. Then she makes her way over to an unfathomably complex machine.”

“Her job is to know everything about it—so that she can fix it.”

“I thought I had the coolest job ever,” Hall says. “I didn’t process the fact that this job is necessary for our entire world to exist as it does.”

“The piece of equipment that the entire world has come to rely on—and she is specially trained to handle—is called an extreme ultraviolet lithography machine.”

“It’s the machine that produces the most advanced microchips on the planet. It was built with scientific technologies that sound more like science fiction—breakthroughs so improbable that they were once dismissed as impossible. And it has transformed wafers of silicon into the engines of modern life.”

“Even today, there are only a few hundred of these EUV machines in existence—and they are ludicrously expensive. The one that Hall maintains cost $170 million, while the latest models sell for roughly $370 million.”

==“ASML’s extreme ultraviolet lithography machine can cost around $370 million and require three 747s to transport.”==

“But maybe the most remarkable thing about these invaluable machines is that they’re all made by the same company: ASML.”

“ASML is the glue holding the chip business together. That’s because this one Dutch company is responsible for all of the EUV lithography systems that help make the chips in so many of your devices. Like your phone. And your computer. And your tablet. And your TV. Maybe even your car, too.”

“These machines have become indispensable. And they depend on the invisible work of Brienna Hall.”

It’s an accessible way to introduce the critical nature of ASML’s core product. Even more important to understand is the absolute culmination of bleeding edge science disciplines that make them possible in the first place.

“EUV machines aren’t so much a marvel as they are a miracle.”

“Their origin story begins 40 years ago in a leaky shed in the Netherlands with the birth of Advanced Semiconductor Materials Lithography—now simply ASML. Back then, printing chips with extreme ultraviolet light was a fantastical idea. Making it a reality would require more time and money than the visionaries who dreamed up this magical technology could have possibly foreseen.”

“It’s a process that involves vaporizing droplets of molten tin and producing light that doesn’t occur naturally on Earth.”

“Or at least that’s the simplest way to understand the the extremely intricate science of extreme ultraviolet lithography.”

There’s a detailed set of graphics in the piece I’d encourage you to check out. It’s a high level schematic that begins to explain the amazing science behind how this process does what it does in these very large machines.

“The droplets get zapped by twin laser pulses—explosions that happen 50,000 times a second. The first pulse flattens them. The second one obliterates them into a plasma that emits the EUV light. That light is then collected using the smoothest mirrors ever invented and directed toward the silicon wafer to etch billions of microscopic transistor patterns.”

“The existential question of the semiconductor industry is how to pack more and more of those transistors on chips to make them faster and faster. The answer: shorter and shorter wavelengths of light. ASML’s first lithography tools created light at wavelengths of 436 nanometers. The current machines have shrunk that number to 13.5 nanometers. That allows them to fabricate chips at resolutions 10,000 times finer than human hair.”

“The more I heard about extreme ultraviolet lithography, the more extraordinary it sounded that anyone ever figured it out.”

The scale of precision of course is almost incomprehensible:

“And there are two things I learned about the EUV tool I saw that I can’t get out of my head:”

-

“ASML teamed up with a German optical company to develop mirrors so flat that if they were scaled up to the size of Germany itself, their largest imperfection would be less than a millimeter.”

-

“The precision of EUV machines is comparable to directing a laser beam from your house and hitting a ping-pong ball on the moon.”

None of this was done overnight. And of course it required close development with key tech and chip companies in Asia:

“It took decades for these absurdly sophisticated machines to make their way from labs to fabs. And until recently, it wasn’t clear if the company’s audacious bet on EUV lithography would ever pay off. In 2012, ASML was strapped for cash and sold a 23% equity stake to Intel, Samsung Electronics and Taiwan Semiconductor Manufacturing, which meant its biggest customers were literally invested in the company’s success.”

“ASML soon ramped up production—very, very slowly. The company delivered the first EUV system in 2010. Not until 2020 did it deliver the 100th. And last year was a busy one: ASML shipped a total of 42 EUV machines.”

And it’s a fundamental fixture in the US driven global tech industry:

“There are still only six companies that own these machines for chip manufacturing. But many others indirectly depend on ASML—including the most valuable companies in history.”

“Apple and Nvidia both design their own chips and outsource production to the fabs of TSMC, which means ASML’s tech is pivotal for making everything from AI data centers to iPhones.”

“EUV machines have become so crucial that the company now employs an army of 10,000 customer-support employees to keep them humming.”

Which of course brings us to the ongoing geopolitical “threading the needle” tussle between the US and China, a key topic I’ve highlighted in my year-end pieces. ASML of course is deep in this tug of war as well, with the Dutch government involved in negotiations between the US and China, as the AI competition continues. And China of course is keenly focused on EUV lithography as a domestic capability with its leading companies like SMIC and others.

Geopolitics aside, it’s important to note the critical role of ASMl in this AI Tech Wave, and its growing importance beyond the New Year. Stay tuned.

(NOTE: The discussions here are for information purposes only, and not meant as investment advice at any time. Thanks for joining us here)